For over a month now we have been engaged in training a new class of MIT EVT members on both the Meche and EE subteams. With a new year comes a new focus, as the Meches push to finalize the design for the entire front compartment and the EEs work toward generating a working test bench along with designing our battery management system (BMS) with the FSAE team.

As usual, we opened up the year with Rango lecturing to the new members about high level concepts.

|

| Rango lecturing at first meeting |

As time progressed, our new members became much more proficient in Solidworks as well as some fabrication techniques, with them being able to make progress toward generating a complete design of the front battery mounting structure, gain a better understanding of the volume available to us in the front section of the car with a point cloud, and beginning to use configurations in Solidworks in order to reduce clutter and make changing any cad easier.

On the EE end, we had our usual meeting about work status and work goals. We currently have a few groups tackling some very big tasks: LV electrical system (think headlights), our custom dashboard for our electrical systems, customized LCD screen for more detailed information, and our new BMS project with MIT's FSAE! We also briefly went over the pros and cons of DC-DC regulators and linear regulators and how we use them in our power distribution network.

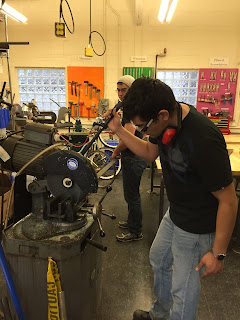

|

| Meche team meeting |

We have also begun doing weekly exec, Meche, EE, and team meetings in order to get better organization as well as to help everyone remain informed as to how their tasks relate to the everyone else's tasks and plan out how they will attack their problem on Saturday.